Content

- 1 Introduction: Practical overview of the Powerful Mobile Solar Generator PV Clean Energy

- 2 Key components and how they work

- 3 Power, capacity and a practical spec comparison

- 4 Realistic performance calculations and examples

- 5 Installation, safety and maintenance

- 6 Practical deployment scenarios

- 7 Charging strategies and maximizing harvest

- 8 Selection checklist when buying

- 9 Field tips: installation and everyday use

- 10 Conclusion: realistic expectations for Powerful Mobile Solar Generator PV Clean Energy

Introduction: Practical overview of the Powerful Mobile Solar Generator PV Clean Energy

The Powerful Mobile Solar Generator PV Clean Energy concept is focused on delivering portable, reliable DC and AC power from photovoltaic (PV) sources in a compact, user-friendly package. This article breaks down design decisions, real-world performance, charging strategies, safety measures, and selection criteria so you can evaluate, deploy, and maintain a mobile solar generator for camping, emergency backup, light construction, or remote work sites. The emphasis here is practical: how these systems produce, store and deliver usable electricity; what trade-offs to expect; and step-by-step recommendations for everyday use.

Key components and how they work

A functional Powerful Mobile Solar Generator PV Clean Energy system includes four core subsystems: solar PV array, charge controller (MPPT preferred), battery energy storage, and an inverter/AC output stage. Understanding each component and its interaction is essential for sizing the system correctly and achieving expected runtime.

Solar PV array

The PV array converts sunlight to DC power. For mobile setups, high-efficiency monocrystalline panels are common because they provide the highest watt-per-area ratio. Panels are typically paired with quick-connect MC4 cables and folding frames for portability. When sizing, account for peak-sun-hours (PSH) at your location and derating factors such as temperature, soiling, and cable losses.

MPPT charge controller

An MPPT (Maximum Power Point Tracking) charge controller ensures the PV array operates at optimal voltage/current to maximize energy harvest. MPPT controllers can increase energy capture compared with PWM controllers—particularly under low-light or partial-shade conditions common in mobile use.

Battery storage

Battery chemistry choices—lead-acid (AGM/Gel), LiFePO4, or other lithium variants—define usable capacity, cycle life, weight, and safety. LiFePO4 is increasingly popular in mobile generators for its higher cycle life, greater usable depth-of-discharge, and lower weight compared to lead-acid, though at higher upfront cost.

Inverter and power management

The inverter converts stored DC to AC for household appliances. Pure sine-wave inverters provide clean power compatible with sensitive electronics. Integrated systems often include smart battery management, output prioritization, and multiple output types (USB, 12V DC, 120/230V AC).

Power, capacity and a practical spec comparison

Below is a concise comparison table that helps translate technical specs into real-world expectations. Use it to match a Powerful Mobile Solar Generator PV Clean Energy unit to your loads and runtime needs.

| Specification | Practical meaning | How to use it |

| PV input (W) | Peak panel power the controller accepts | Match PV wattage to controller rating; avoid oversize without checking specs |

| Battery capacity (Wh) | Energy stored; defines runtime | Estimate runtime = Wh / device W; allow 20–30% inverter overhead |

| Continuous inverter power (W) | Max sustained AC load | Sum all AC loads; don’t exceed continuous rating |

| Peak (surge) inverter power (W) | Short bursts for motor starts or compressors | Ensure surge covers startup draw for appliances like pumps |

Realistic performance calculations and examples

To predict runtime, list the devices you intend to run, note their wattage, and calculate total daily consumption (Wh). Example: a laptop (60W) + LED lights (20W) + phone charging (10W) used for 5 hours yields (60+20+10)*5 = 450 Wh. Account for inverter inefficiency (typically 85–92%); divide battery usable Wh by adjusted load to estimate hours.

Example: sizing for a day-use setup

- Daily load target: 600 Wh (small workstation and basic appliances)

- Recommended battery: 1000 Wh LiFePO4 (usable ~900 Wh)

- Recommended PV: 200–300 W array with 4–6 peak-sun-hours to replenish daily use

Installation, safety and maintenance

Correct setup reduces risk and increases longevity. Follow manufacturer instructions for PV mounting, keep connections tight and weatherproofed, and ensure ventilation for battery enclosures. Use appropriately rated fuses and a dedicated transfer switch for AC grid-interactive deployments.

Battery safety and lifecycle tips

- Avoid deep discharges below the recommended state-of-charge—LiFePO4 typically allows 80–90% DoD, lead-acid much less.

- Keep batteries in a temperature-controlled environment; extreme heat shortens life.

- Inspect terminals and cables monthly for corrosion or loose connections.

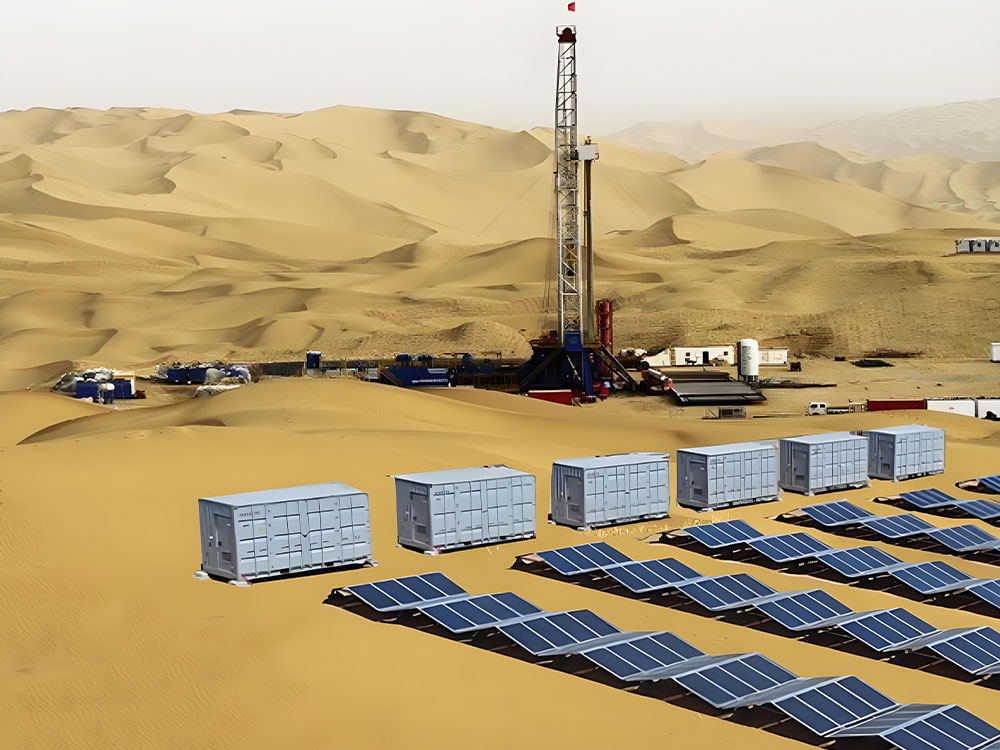

Practical deployment scenarios

A Powerful Mobile Solar Generator PV Clean Energy unit excels in multiple contexts. Below are practical deployment templates with recommended system sizing to match typical use cases.

Camping and van life

- 200–500 Wh battery and 100–300 W portable panels for lights, phone, and a laptop.

- Flexible panels or folding kits simplify stowing and setup.

Emergency backup for small home loads

- 2–5 kWh battery bank, 1–2 kW inverter for refrigerators, medical devices, and communications.

- Use a transfer switch to isolate circuits during grid outages.

Charging strategies and maximizing harvest

To keep a Powerful Mobile Solar Generator PV Clean Energy system running reliably, optimize array orientation, tilt, and MPPT settings. For mobile use, a variable-tilt frame helps capture low-angle sun in winter, while parallel/series panel wiring strategies affect voltage and current behavior depending on the controller’s input limits.

Parallel vs series panel wiring

Series wiring raises voltage (useful for long cable runs and MPPT controllers with high input voltage), while parallel wiring increases current (useful when controller voltage is limited). Always check the controller's Voc and Isc limits before wiring panels.

Selection checklist when buying

Use this checklist to compare models and avoid common pitfalls. Prioritize realistic usable Wh (not just nominal battery capacity), continuous inverter rating, surge capability, and serviceability.

- Verify usable battery Wh (battery capacity × recommended DoD).

- Confirm continuous and peak inverter ratings against your highest expected loads.

- Check PV input limits, MPPT efficiency, and supported panel voltages.

- Look for integrated BMS, easy firmware updates, and accessible customer support.

Field tips: installation and everyday use

When using the generator in the field, place panels where shading is minimal, keep connectors dry, and rotate panels during the day if practical to follow sunlight. For mobile rigs exposed to vibration, periodically check terminal torque and cable strain reliefs.

Conclusion: realistic expectations for Powerful Mobile Solar Generator PV Clean Energy

A well-specified Powerful Mobile Solar Generator PV Clean Energy setup provides flexible, quiet power with low operational cost and rapid deployment. Success depends on correct sizing for load and site conditions, conservative safety practices, and choosing components that match real-world needs (usable Wh, inverter capability, and PV input limits). Use the tables and checklists above to create a system that reliably supports your devices while remaining portable and serviceable in the field.

English

English 中文简体

中文简体 عربى

عربى