Wheel-type solar PV containers are engineered with several structural and mechanical design features to ensure safe and stable transportation, especially when moving across challenging terrains or between remote sites. These mobile units must comply with both electrical system integrity and roadworthiness standards. Below is a detailed explanation of the key features:

1. Reinforced Chassis and Container Frame

Heavy-Duty Steel Frame: Built with high-tensile steel or galvanized steel to withstand the stresses of towing and uneven ground.

Shock-Absorbing Design: Frame design includes flex tolerance and vibration resistance to protect solar modules and battery systems.

Twist-Lock Corners or ISO Container Standards: For secure lifting, stacking, and compatibility with standard transport equipment like flatbed trucks or cranes.

2. Road-Legal Axles and Suspension System

Multi-Axle Support: Depending on load size, dual or triple axles distribute weight evenly to prevent overloading and reduce sway during motion.

Leaf Spring or Air Suspension: Dampens road vibration and prevents mechanical shock to sensitive electronics and solar modules.

Hydraulic Stabilizers (Outriggers): Deployed when stationary to level the container and prevent tipping, especially during solar array deployment.

3. Retractable or Lockable Solar Panel Racks

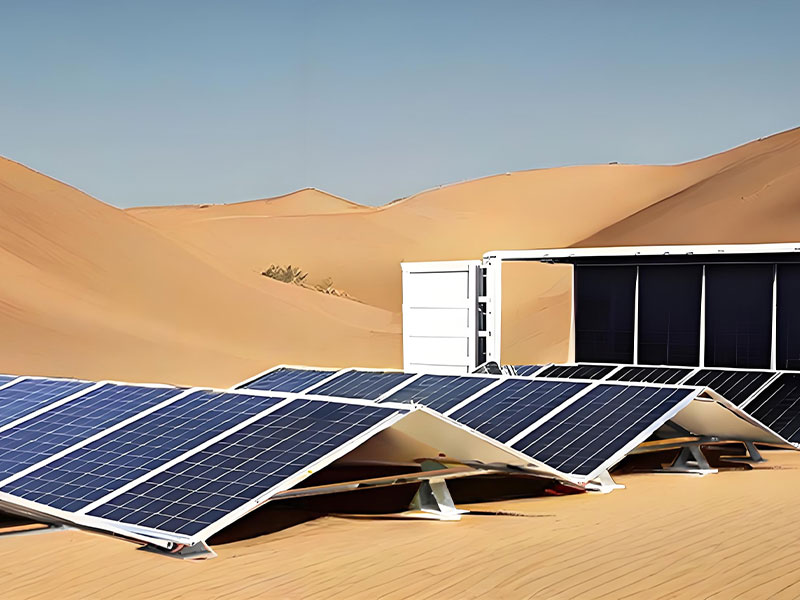

Foldable Array Mechanism: Allows solar modules to be retracted and locked into the container body during transport, minimizing wind resistance and panel damage.

Mechanical Locks and Latches: Secure the array during motion to prevent accidental deployment.

Gas Springs or Hydraulic Arms: Facilitate safe folding/unfolding of solar panels with minimal manual intervention.

4. Brake and Lighting Systems

DOT or EU-Compliant Braking Systems: Integrated mechanical or electric brakes on trailer wheels for road safety.

Road-Grade Lighting and Signal Systems: Includes brake lights, turn signals, reflectors, and license plate mounts to meet transport regulations.

5. Weatherproof and Vibration-Resistant Enclosures

IP65–IP67 Rated Cabinets: Protect inverters, batteries, and controls from dust, water, and road debris.

Anti-Vibration Mounts: Used for electrical equipment such as battery racks and inverters to prevent mechanical damage during movement.

6. Towing and Hitch Compatibility

Universal Tow Hitch: Designed to connect to standard vehicles for overland movement (ball hitch, pintle hook, or fifth wheel).

Swivel Jacks and Drop Legs: Allow manual height adjustment to match varying hitch heights and stabilize the unit when stationary.

7. Load Distribution and Weight Balance

Optimized Center of Gravity: Batteries and inverters are positioned low and centrally to avoid tipping and reduce trailer sway.

Weight Ratings and Load Certification: Designed to meet axle load limits and gross vehicle weight ratings (GVWR) for compliance with regional transport laws.

8. Modular and Stackable Design (Optional)

Containerized Format: Some models are built into ISO-standard container dimensions for intermodal transport by sea, rail, or air.

Stacking Compatibility: Enables multiple units to be moved together or stored efficiently.

To ensure safe transportation, wheel-type solar PV containers incorporate:

Durable structural framing

Foldable mechanical solar arrays

Certified road mobility systems

Equipment protection from vibration, weather, and impact

These features support reliable operation in off-grid, military, or emergency scenarios while maintaining compliance with transport and safety standards like ISO 668, EN 12195, and FMVSS.

English

English 中文简体

中文简体 عربى

عربى